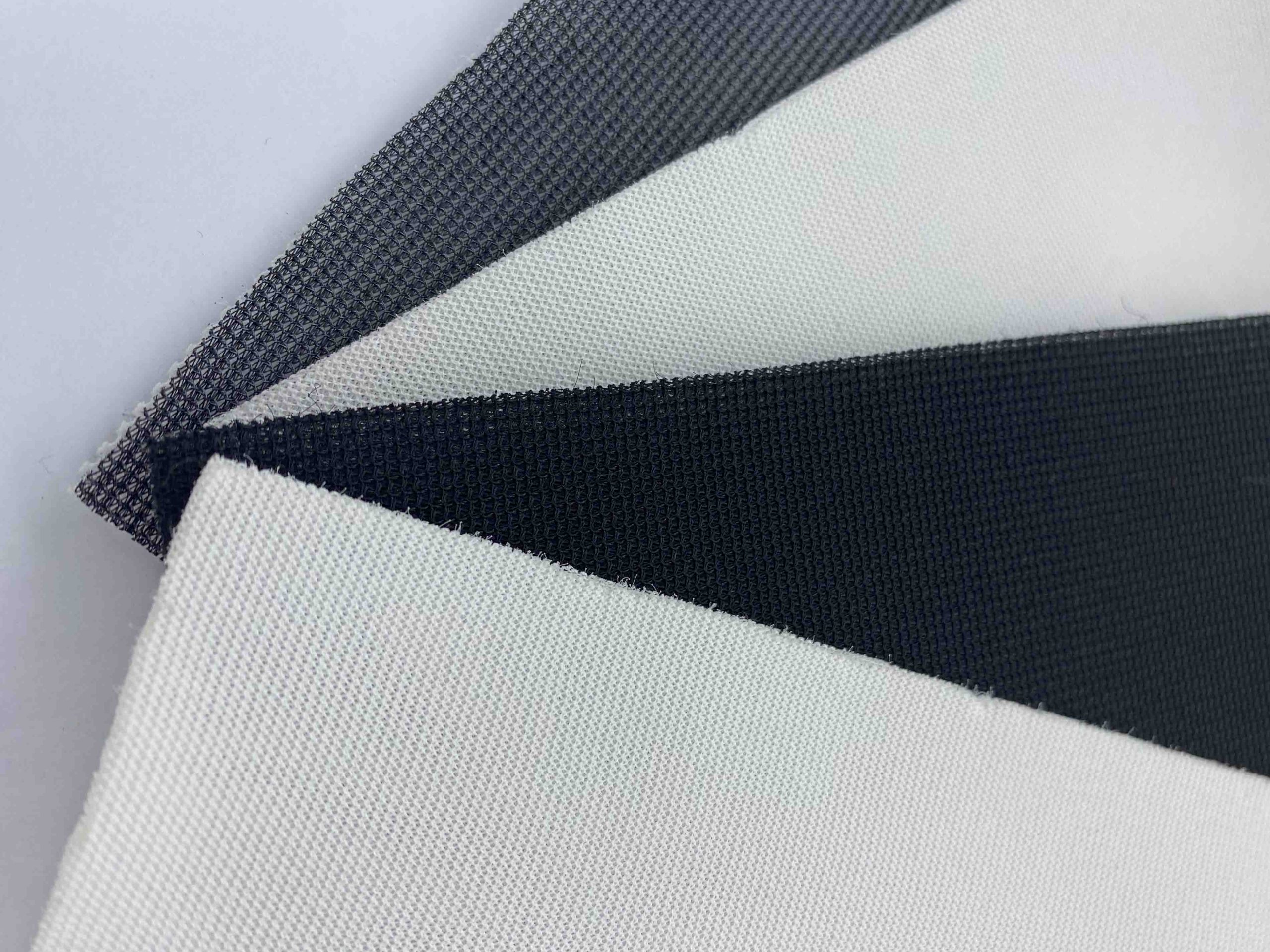

What is 3D Air Mesh Fabric

3D Air Mesh Fabric is a high-performance fabric that uses a unique three-dimensional weaving process to create a network of interconnected, three-dimensional mesh structures. This design significantly enhances the fabric’s breathability and comfort compared to traditional flat fabrics. 3D Air Mesh Fabric effectively promotes airflow, dissipates excess heat and moisture, and provides a more comfortable experience for users. As a key component of vehicle upholstery fabric, it plays a crucial role in automotive interior design.

Weaving Process

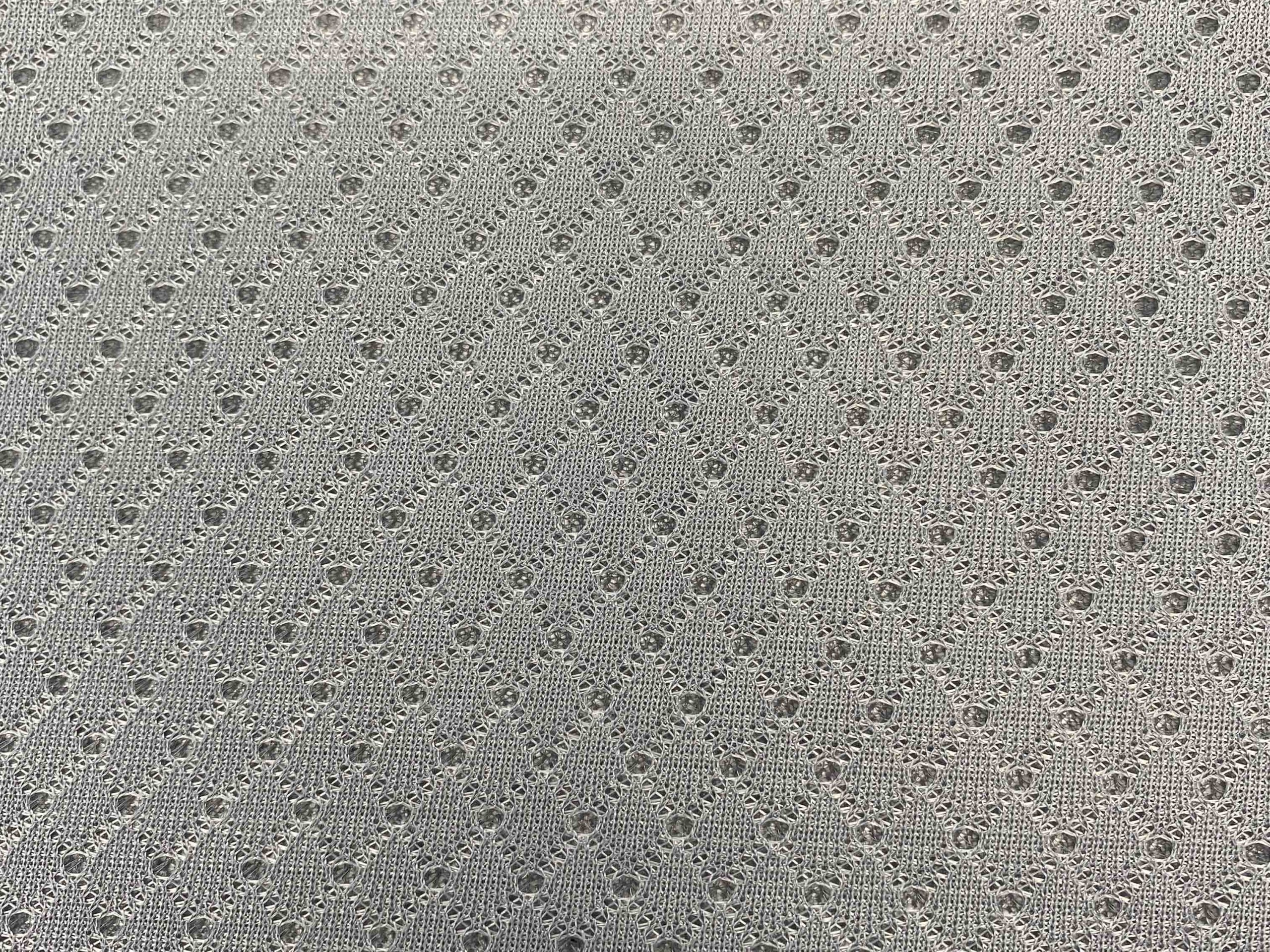

The weaving process for 3D Air Mesh Fabric involves several key steps:

1. Material Selection: Typically made from high-performance synthetic fibers such as polyester or nylon, these materials are lightweight yet highly durable and resistant to tearing.

2. Three-Dimensional Weaving: Advanced weaving machines are used to create the three-dimensional mesh structure, forming multiple air pockets within the fabric. This process enhances the fabric’s flexibility and elasticity.

3. Post-Treatment: After weaving, the fabric undergoes heat treatment, coating processes, and other post-treatments to further enhance its properties, such as water resistance, stain resistance, and UV protection.

Applications in Automotive Interiors

3D Air Mesh Fabric is widely used in automotive upholstery, including:

– Seat Covers: As a major application of vehicle upholstery fabric, 3D Air Mesh Fabric is commonly used for car seat covers due to its excellent breathability and comfort, especially in hot weather.

– Headliner Padding: Used in automotive headliners, it effectively absorbs sound, improves the acoustic environment within the vehicle, and provides a visually appealing effect.

– Door Linings: In door linings, 3D Air Mesh Fabric enhances the overall interior quality and adds a sense of openness to the space.

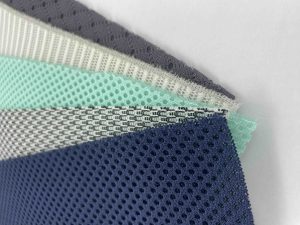

Advantages of 3D Air Mesh Fabric

1. Enhanced Breathability: The three-dimensional mesh structure allows for excellent airflow, keeping seats dry and preventing moisture and odors from accumulating even during extended use.

2. Superior Insulation: The natural convection of air through the fabric creates an insulating layer, effectively blocking external heat from entering the vehicle, reducing the need for air conditioning, and improving fuel efficiency.

3. High Durability: The fabric is treated to offer exceptional wear resistance and tear strength, maintaining its appearance and functionality even under harsh conditions.

4. Increased Comfort: The unique three-dimensional structure provides better support and elasticity, ensuring a comfortable seating experience, even during long drives.

5.Environmental Friendliness: Many 3D Air Mesh Fabrics are made from recyclable materials, meeting environmental standards and reducing ecological impact.

Conclusion

As a cutting-edge vehicle upholstery fabric, 3D Air Mesh Fabric offers an ideal solution for enhancing the comfort and aesthetics of automotive interiors. With growing consumer expectations for high-quality automotive interiors, 3D Air Mesh Fabric is becoming increasingly popular and is expected to be a leading choice for future automotive upholstery materials.

Application display

About us

SI BEI XIU

For more than 15 years production and R & D of double raschel knitting machinery and 3D spacet fabrics, SpecialTex was set up in 2023 by a frienotechnical team.

We aim at the pain points ofthe 3D spacer fabricsand act as a solution provider.

Innovation is our passion,let’ s do best and discovery the value inside of the fabrics.

FAQ

Q: May I get a sample for reference ?

A: Yes , Of course. You can get A4 size sample from us.

Q:How canIget the price ofthe fabric whatlwant ?

A:1、Please give us the exactly composition,construction,densitywidth,weight also more rquirements of fabric to us. According toyour requirements, we can give you a similar sample and price.

2、You can sendus asample,We can according toyour samplegiveyouaexact price.

3、lf vou don’t know the details of the fabric .You can show apicture of the fabric and tell us the usage, we can according toour experience give you a estimated price. But the exact pricemust after we check the original sample.

Q: Do you accept small quantity order ?

A: Yes ,small order is welcomed . We are willing to grow up withyou together.

Q:What about the payment ?

A: T/T at sight is acceptable.

Q: What kind of transport service provided ?

A: FOB and ClF is the usual way . Besides, other is also available.