Crafting mesh fabric involves an intricate process that harmonizes advanced technology with creative artistry. This process entails meticulous stages from inception to finalization, emphasizing excellence, endurance, and ingenuity.

From Choice to Creation

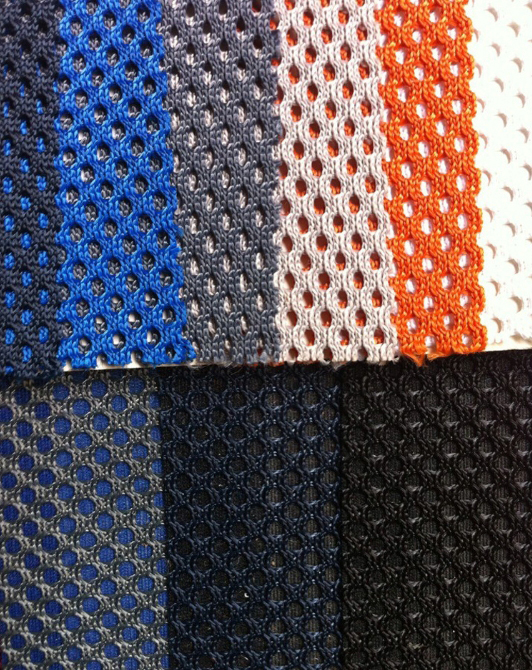

The initial phase revolves around selecting appropriate components. High-quality raw materials, encompassing both organic and synthetic fibers, are fundamental to fabric manufacturing. These undergo intricate weaving or knitting, where technology converges with craftsmanship. This stage is pivotal in crafting a diverse range of mesh fabrics tailored for various purposes.

Organization and Excellence – The Heart of Production

Achieving success in mesh fabric manufacturing hinges on thorough planning and rigorous quality assurance. These procedures ensure top-notch quality from raw materials to the end product, striving for both immediate superiority and long-term viability. This meticulous approach reflects the commitment to fulfilling the market’s appetite for personalized and versatile textile goods.

Supply Chain and Environmental Consideration

A streamlined supply chain and deliberate product design are imperative for facilitating large-scale customization while meeting market requirements. The evolution of the textile industry underscores significant strides in fabric design and utility, consistently mindful of minimizing environmental footprint. Sustainable practices throughout manufacturing and post-processing underscore this dedication to environmental sustainability.

This concise guide aims to spotlight the nuanced procedures underlying mesh fabric manufacturing. Crafted for accessibility, it seeks to deepen comprehension and admiration of the challenges and accomplishments in fabric manufacturing, resonating with students and enthusiasts alike.