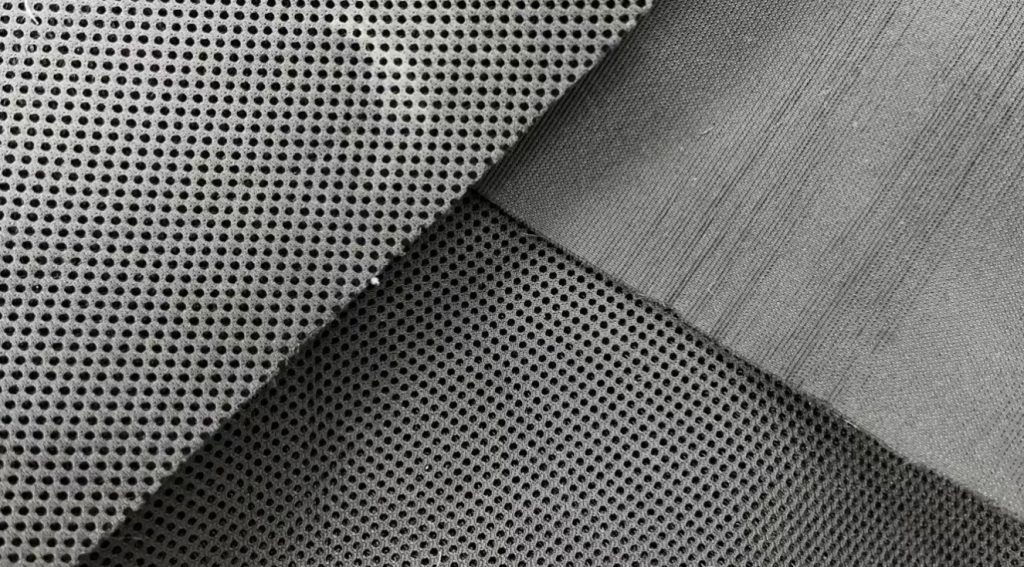

The textile industry is embracing high-quality 3D fabrics, especially 3D meshes, for their mix of style and functionality. This new material brings a revolution to fashion and sports, offering unparalleled comfort and aesthetics.

Varieties and Their Characteristics

3D fabric variations include spacer fabrics, circular meshes, and core 3D meshes. Spacer fabrics, known for their breathability and lightness, are perfect for warm weather. Circular meshes, recognized for softness and flexibility, are ideal for athletic wear. Core 3D meshes provide exceptional support and durability, suited for sports equipment and decorative textiles.

From Historical Mills to Modern Supply Chains

In the 19th century, textile production in mills utilized natural fibers and complex processes. Today, technological advancements and refined supply chain management enable more efficient and sustainable production of 3D fabrics.

Advantages of 3D Fabrics

3D meshes stand out for their breathability and moisture management, ensuring comfort across various conditions. The shift towards using recycled materials or natural fibers for these fabrics aligns with growing environmental sustainability efforts, showcasing the industry’s move towards eco-friendliness.

The Future of Textile Industry

High-quality 3D fabrics, by leveraging technology and sustainability, are setting new benchmarks in the textile sector. This evolution points towards a future where fashion harmonizes with environmental consciousness.